Comi Condor

The origins of Comi Condor go back to 1885 when the company “COMI” was founded. Over 100 years of design, engineering and manufacturing experience have led the present company to occupy a position of leadership in the Italian and world-wide markets in the production of filtering centrifuges for fine chemicals.

In early 1920s, special attention was paid to the development of industrial centrifuges that corresponded to different needs of factories, producing chemical and pharmaceutical substances, paint, silk, wool, dyes, wine, sugar and powders.

In 1972, a new factory was opened in Santa Cristina, equipped with modern workshops for production, design and assembly of all types of industrial centrifuges.

Between the late 80s and early 90s, the production was concentrated on manufacturing centrifuges for the pharmaceutical and fine chemicals industries, with special emphasis on cleaning and compliance with GMP requirements.

Now the company owns two factories: the first - in Settimo Milanese (Milan), and the second - in Santa Cristina (Pavia) with a total staff of about 70 people.

On Italian market Comi Condor offers a much broader range of centrifuges than any other company - more than 3,000 machines have been installed in only Italy.

In 1999, the company received the ISO 9001 certificate (AOQC 9904527).

The main characteristics of COMI CONDOR products are:

- Reliable mechanical components and precise manufacturing procedures

- Surface finishing, which has an important role in pharmaceutical industry

- Installation of electric and electronic components of high reliability and advanced technology

The strong point of the company is its flexibility to follow the Clients’ specifications to customize the machines.

MediBalt Ltd - representative of Comi CondorPriedaines Str. 13-1, LV-1029 Riga, Latvia

Phone Riga: +371 67373144, Fax: +371 67373143

Phone Moscow: +7 (499) 703-04-06

E-Mail: info@medibalt.com

|

In the early 1920s particular attention was given to the development of industrial centrifuges to suit the various needs of factories producing chemicals, pharmaceuticals, paints, silks, wools, dyes, wines, sugar and powders.

In the meanwhile the company “TORNIOTECNICA”, previously engaged in specialized sheet metal work, began in 1959 manufacturing its own range of centrifuges under the name “CONDOR”, The leader behind this new venture was Giuseppe Poma who had many years of experience in the field of centrifuges ( he had previously been production manager at “COMI”).

In 1960, TORNIOTECNICA produced the first prototype of a completely hydraulically-controlled centrifuge, particularly suitable for hazardous areas, followed in 1962 by the “TURBIN/MATIC” series with bottom discharge.

In 1964 the technical and manufacturing arms responsible for “COMI” centrifuges were sold by Westinghouse to the company “TORNIOTECNICA metalli in lastra”, which adopted the new name of “TORNIOTECNICA COMI CONDOR COSTRUZIONI MECCANICHE”. The company was owned by G. Poma and L. Cavallotti. The acquisition of “COMI” by “TORNIOTECNICA” gave a clear direction to the production of the company, which had meanwhile built the new factory in Settimo Milanese, towards the specialization in centrifuges, developing and manufacturing new models and new types for chemical and pharmaceutical plants.

In 1972 Torniotecnica opened the new Santa Cristina factory, designed and equipped with modern workshops for the manufacture, construction and assembling of industrial centrifuges of all types.

It was during these years that the company began producing circular self-cleaning vibrating screens for the chemical, pharmaceutical, mineral, food and ceramics industries.

Between the end of the ’80 and the beginning of the ’90 the production was concentrated on the manufacture of centrifuges for the Pharmaceuticals and Fine chemicals industry, with special emphasis on cleaning and compliance with the GMP requirements.

Since it was established in 1885, the company has grown consistently to reach its present position of leadership in the Italian and world markets in the field of fine chemical filtering centrifuges.

On the home market, COMI CONDOR offers a more complete range of centrifuges than any other company, as witnessed by the fact that over 3000 of its machines have been installed in Italy only.

COMI CONDOR has two plants, one in Settimo Milanese (Milano) and the other in Santa Cristina (Pavia), with a total of around 70 employees.

The Settimo Milanese site covers an area of 1,500 m2. This includes the offices, administrative and financial divisions, technical department, workshop for the maintenance and overhaul of centrifuges and the manufacture and assembly of vibrating screens.

The Santa Cristina factory covers some 5,190 m2, with a total site area of 25,000 m2. This factory houses all departments for the production, assembly and testing of the centrifuges.

Pilot centrifuges are also available for testing on clients’ own sites in Italy or abroad.

In 1999, the company was awarded ISO 9001 certification (AOQC 9904527).

After sales service has also been strengthened by the recruitment of specialist personnel.

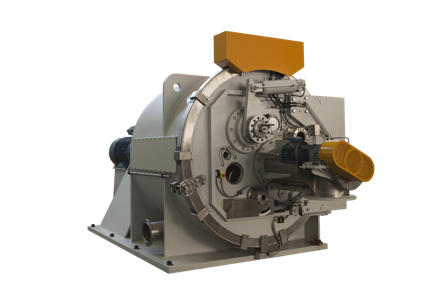

Models