Principle of operation:

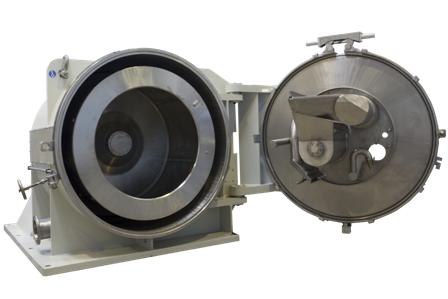

Feeding

The solid-liquid suspension is fed from two feeding pipes (main one and secondary one) into the centrifuge and under the action of centrifugal force it moves towards the filter cloth, placed on a solid drum with perforations in the rear side. The solid part of the suspension is retained by the filter cloth forming a cake, while the liquid filters through the cake and the cloth and is discharged through the holes of the basket. The liquid is discharged via siphon installed at the rear side of the basket.

Skimming

The use of the secondary feed pipe allows a formation of a pond at the front side of the basket and a skimmer, which can be submerged into the pond, can discharge the proteins or the fibers which float on the pond surface as they are lighter than the water.

Centrifugation

After completion of the feeding phase, the centrifuge is accelerated to the maximum speed and maintained for a given time to achieve the level of residual humidity of the product being processed. At the end of the centrifugation, the centrifuge decelerates to the loading speed for discharging.

Discharge

The discharge takes place by means of the peeling knife. After reaching the discharge speed, the knife increment command is activated and the knife starts cutting the cake conveying the product into the discharge chute or screw conveyor and from it to the dryer).

Back wash

After a number of cycles (5÷10), the heel cake (8÷10 mm) can become no longer filterable, so that thanks to the action of the “back wash” system, which can resuspend it, it can become filterable again, making it not necessary for its removal for many cycles (normally once a day).

Heel cake removal

After a number of “back washes”, the heel cake of about 8÷10 mm remains on the filtering cloth. This heel cake can be removed, to improve the filterability of the product, through a suitably large water flow through the main feed pipe. The removed product is collected by the knife, positioned close to the filter cloth, and conveyed through the screw conveyor into the solids recovery systems.

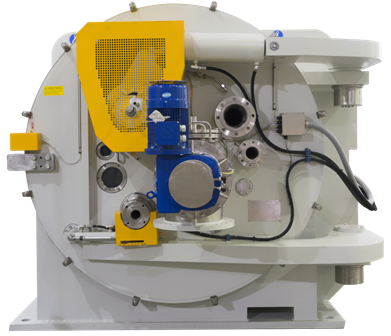

Centrifuge cleaning (C.I.P.)

The centrifuge should be cleaned at every change of product to avoid "cross-contamination" between the processed products. The centrifuge cleaning system, fully automated, is composed by 2 main stages: Washing Machine Effect and cleaning with spray balls, which can be alternated to achieve maximum cleaning and to optimize the consumption of the cleaning liquid.

Washing Machine Effect (WME)

The centrifuge is filled with the washing liquid up to a predetermined height and is put in rotation. During the sequence of the automatic washing the basket rotates clockwise and counterclockwise; the knife goes in and out so that the washing liquid reaches all the points of the process area, including the discharge chute.

Cleaning with spray balls

The washing liquid is sprayed through spray balls on all the surfaces of the process area to completely remove the residues of product still present.

|

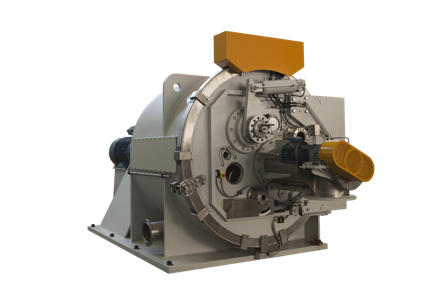

Centrifuge Model:

HX/L/S

|

Basket diameter

|

Filtering surface

|

Cake volume

|

Max load

|

Max speed

|

G factor

|

Weight with no motor

|

With inertia base and motor

|

|

Unit

|

mm

|

m²

|

dm³

|

kg

|

RPM

|

xg

|

kg

|

kg

|

|

1250/650

|

1250

|

2,55

|

346

|

484

|

1300

|

1180

|

6500

|

16000

|

|

1250/800

|

1250

|

3,14

|

426

|

596

|

1300

|

1180

|

8000

|

20000

|

|

1300/850

|

1300

|

3,47

|

500

|

700

|

1250

|

1135

|

8500

|

21000

|

|

1700/920

|

1700

|

4,91

|

922

|

1290

|

1030

|

1000

|

14000

|

35500

|

|

1700/1150

|

1700

|

6,14

|

1152

|

1614

|

1030

|

1000

|

15500

|

42000

|

|

1850/1300

|

1850

|

7,55

|

1520

|

2130

|

985

|

1003

|

26000

|

58000

|

|

2000/1440

|

2010

|

9

|

2023

|

2832

|

950

|

1000

|

32500

|

70000

|

|

2100/1550

|

2100

|

10,2

|

2328

|

3260

|

900

|

950

|

33500

|

73000

|

- Installation on concrete or carbon steel inertia base with anti-vibration dampers;

- Oil bearings lubrication for all models;

- Knife blade fixed without use of bolts;

- The endless filter cloth, thermo-welded, in polypropylene or other materials of various sizes and micrometry, is easily replaceable;

- Materials in contact with the product: all stainless steels and special alloys available, such as AISI 316L, AISI 904L, Hastelloy, Monel, ALLOY 59, 254 SMO, NICKEL, TITANIUM, SAF 2205. HALAR coatings (ECTFE), also antistatic and FDA certificated, Teflon ETFE, HARD RUBBER.