shawpak

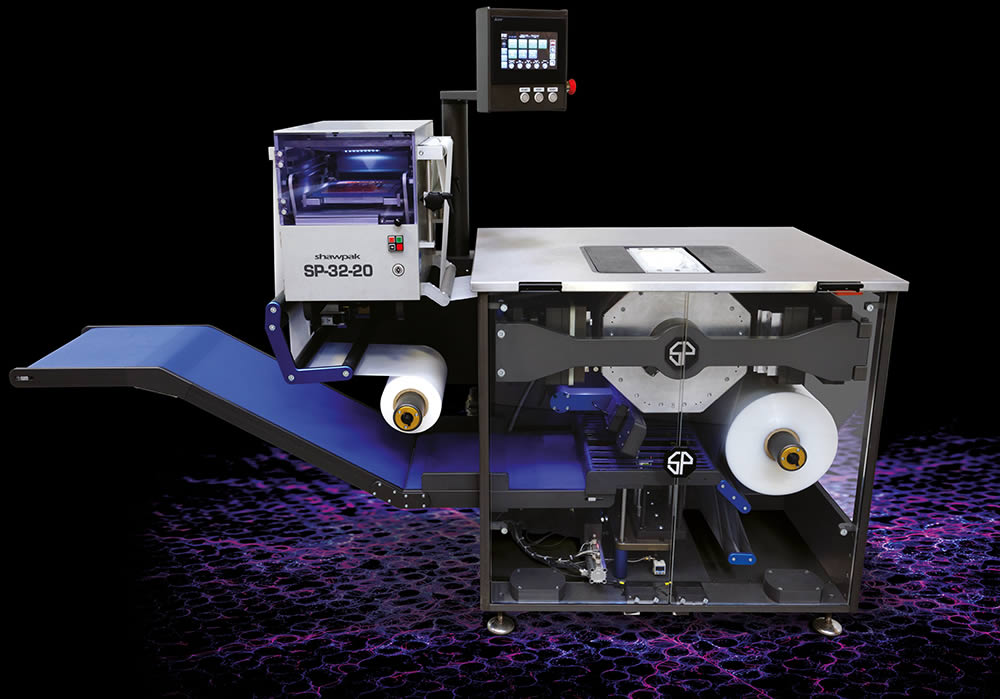

The shawpak is a revolutionary machine offering a thermoforming solution to your packaging needs that is totally unique.

The machine has been designed and developed over the past two years by a team of engineers from Riverside Medical Packaging.

Amazingly compact, portable, flexible, energy efficient and above all, very competitively priced.

This method means no gripper chains and no trim, leading to much less maintenance, contamination and downtime. Coupled with this, the product is placed into the mould that creates the form, meaning no blister edges can ever be trapped in the seal.

The heart of the machine is a servo driven indexing drum which transports the webs through the machine. The drum is surrounded by forming, sealing and cutting stations. The product is simply loaded in to the top of the tooling drum and ejected out of the base onto a discharge conveyor.

The drum houses the forming cavities. These can be as simple as a basic rectangle through to a contoured 3D surface to match the product to be packed. Pack forms can be changed either by replacing the drum or by individual pocket inserts.

The design is based on producing packs in a single lane format. This simplifies the operation of the machine and leads to precise control of forming and, more critically, sealing parameters. This control leads to incredible repeatability which can be recorded and data logged.

Another great benefit is that coding and labelling is kept simpler on a single lane basis.

shawpak will meet the majority of tasks both economically and efficiently.