-

- Complete cycle (from loading to discharging) is carried out without contact between the operator and the product, which allows working with toxic and flammable products.

- TM centrifuge has relatively small foot print and its installation requires limited headroom.

- CIP washing system guarantees the absence of cross-contamination.

- The centrifuge can be kept under inert atmosphere with a small overpressure. Inertization is carried out by the Nitrogen.

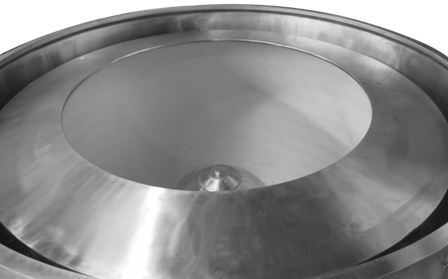

- The suspension is fed via static feed pipe or via rotating disc, which is perfectly suitable for fast filtering product as it avoids vibrations granting an even cake distribution.

- Filter cloth is fixed to the rotor by means of extension rings, which makes its replacement fast and comfortable.

- The cycle of the centrifuge can be manual and automatic. They can store many recipes with different processing times, rotating speeds, iteration and sequence phases.

- Three operating modes of the centrifuge are available: fully automatic (via PLC or DCS), semiautomatic and manual.

-

Loading

The solid-liquid suspension is fed from the loading pipe (or optionally via a rotating disc) into the centrifuge and under the action of centrifugal force it moves towards the filter cloth, placed on a perforated basket. The solid part of the suspension is retained by the filter cloth forming a cake, while the liquid filters through the cake and the cloth and is discharged through the holes of the basket. The growth of the cake thickness is controlled by a mechanical or laser detector, which can automatically stop the loading phase when the desired cake thickness is reached.

Cake washing

Washing of the product is used to remove any impurities present in the cake. Washing liquid is distributed on the product, along the entire length of the basket, through nozzles suitably distributed on the washing pipe (or optionally via a rotating disc). The liquid passes through the product, purifying it, and then passes from the filter cloth and the holes of the basket.

Centrifugation

Once completed the washing phase, the centrifuge is accelerated to the maximum speed and maintained for a given time to achieve the level of residual humidity of the product in processing. At the end of the centrifugation, the centrifuge decelerates to the discharge speed.

Discharge

The discharge takes place by means of the scraping knife. After reaching the discharge speed, the knife increment command is activated and the knife starts cutting the cake conveying the product into the discharge chute and from it to the product collection systems (drums, bin, dryers, mixers).

Heel cake removal

At the end of the product discharge phase, a heel cake of about 4÷5 mm remains on the filtering cloth. This heel cake can be removed, to improve the filterability of the product, through the high-pressure nitrogen blow from the rear part of the baskiet or/and via nozzles placed on the knife. The removed product is collected by the knife, positioned close to the filter cloth, and conveyed through the chute into the collection systems.

Centrifuge cleaning (CIP)

The centrifuge should be cleaned at every change of product to avoid "cross-contamination" between the processed products. The centrifuge cleaning system, fully automated, is composed by 2 main stages: Washing Machine Effect and cleaning with spray balls, which can be alternated to achieve maximum cleaning and to optimize the consumption of the cleaning liquid.

Washing Machine Effect (WME)

The centrifuge is filled with the washing liquid up to a predetermined height and is put in rotation. During the sequence of the automatic washing the basket rotates clockwise and counterclockwise; the knife goes in and out so that the washing liquid reaches all the points of the process area, including the discharge chute.

Cleaning with spray balls

The washing liquid is sprayed through spray balls on all the surfaces of the process area to completely remove the residues of product still present.

-

|

Centrifuge Model:

TM

|

Basket diameter

|

Basket length

|

Filtering surface

|

Cake volume

|

Max load

|

Max speed

|

G factor

|

Centrifuge weight

|

|

Unit

|

mm

|

mm

|

m²

|

dm³

|

kg

|

RPM

|

xg

|

kg

|

|

800/250

|

800

|

250

|

0,63

|

63

|

79

|

1650

|

1216

|

1500

|

|

800/400

|

800

|

400

|

1,01

|

100

|

125

|

1500

|

1006

|

2000

|

|

1000/500

|

1000

|

500

|

1,57

|

200

|

250

|

1200

|

805

|

4100

|

|

1000/630

|

1000

|

630

|

1,98

|

250

|

312

|

1200

|

805

|

4250

|

|

1250/700

|

1250

|

700

|

2,75

|

400

|

500

|

1000

|

700

|

6400

|

|

1250/800

|

1250

|

800

|

3,14

|

500

|

625

|

1000

|

700

|

6700

|

|

1600/800

|

1600

|

800

|

4,02

|

820

|

1025

|

900

|

724

|

12000

|

|

1600/1000

|

1600

|

1000

|

5,03

|

1025

|

1280

|

900

|

724

|

13000

|

|

1700/1190

|

1700

|

1190

|

6,3

|

1377

|

1721

|

850

|

686

|

14500

|

|

1850/1250

|

1850

|

1250

|

7,26

|

1710

|

2140

|

800

|

643

|

16500

|

Drive: electric motor and drive with frequency converter for the rotor and for filling (option) of the rotating cone. The knife and opening of the cover are hydraulically controlled.

Filtration: polypropylene fabric or PTFE fabric.

Gas tightness: in accordance with DIN 24400, 400 mm H2O.

Cleaning in place: No cross-contamination due to the CIP cleaning system. To improve cleaning procedure, it is also possible to completely flood the process area (complete flooding of the machine). Automatic rinsing cycle consists of a sequence of alternating washes applying these two methods.

Suspension: There are two possible solutions:

- Three columns of suspension

- Suspensions on an inert platform with viscous dampers to avoid the use of heavy concrete foundations

Surface polishing: Multiple levels of polishing - up to mirror and / or electrochemical polishing.

Structural materials: All kinds of stainless steel and special alloys are available, such as AISI 904 L, AISI 316 L (DIN 1.4404), HASTELLOY, MONEL, ALLOY 59, 254 SMO, NICKEL, TITANIUM, SAF 2205.

Internal lining from HALAR (ECTFE), TEFLON ETFE, EBONITE.