Model description

-

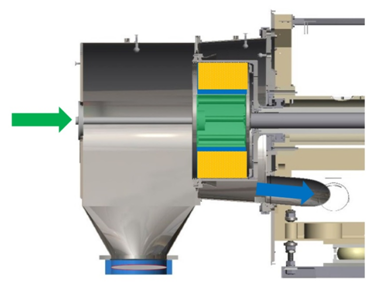

- Absolutely no contact between product and operator

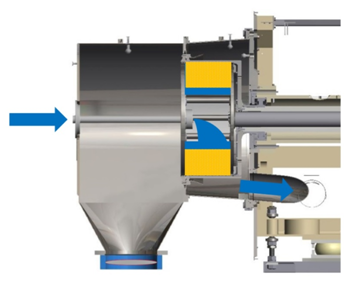

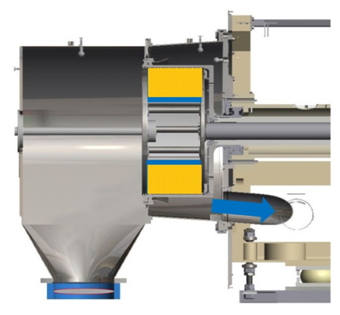

- Even cake distribution due to the horizontal design

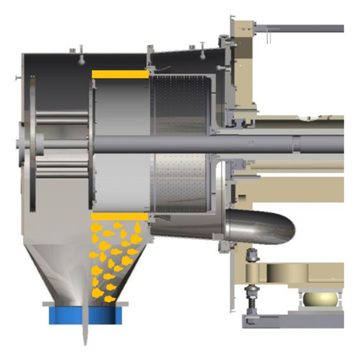

- Due to the short discharging time and the complete elimination of the heel cake at every cycle, it’s possible to work with thin cakes allowing to separate products with low filtering properties (fine particles, high compressibility), achieving a very good/uniform cake washing;

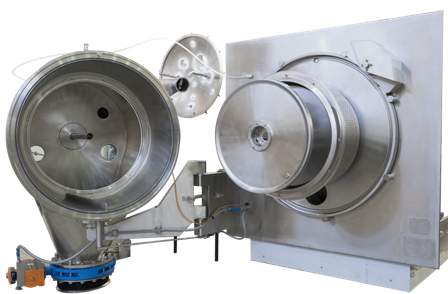

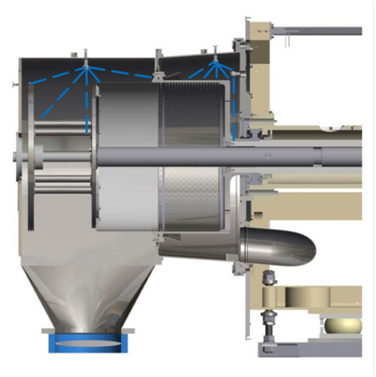

- COMI CONDOR has developed a completely openable casing that allows the inspection of the rear wall of the basket and avoid dead zones in the process area.

- Capability of pre-drying or even drying (for some products) thanks to the HCS (Hyperbaric Centrifugation System), supplying N2 at max 6 barg into the basket for further dewatering the capillaries inside the cake (reduction of the residual moisture)

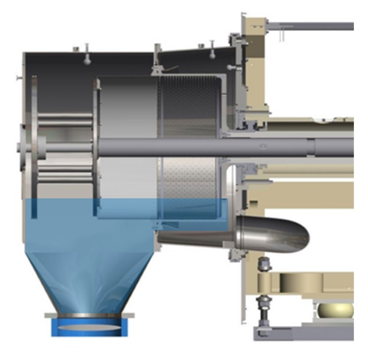

- C.I.P.: very good possibility of achieving an efficient C.I.P. (Clean In Place) thanks to the use of the W.M.E. (Washing Machine Effect) and spray balls.

- Easy installation (isolation from unbalance loads by means of rubber dumpers);

- Through the wall installation;

- No contact between operator and product during operation;

- Electromechanical filter cloth inversion (oil free execution);

- Various levels of containment at solids discharge

- Complete FDA validation documentation