Model description

-

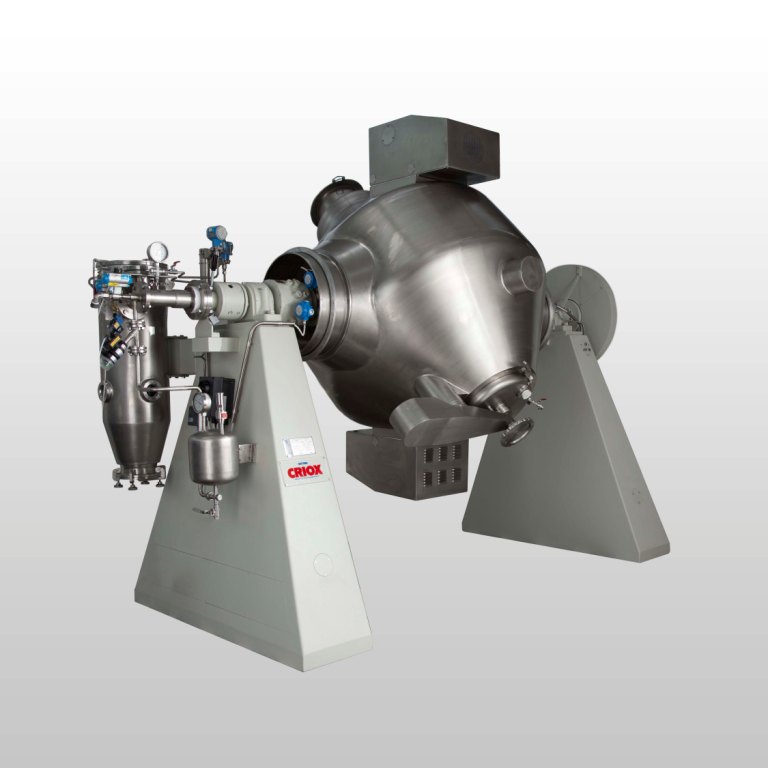

- Bi-conical rotating drying chamber of CRIOX System allows total and continuous revolution of the mass to be dried and an extremely homogeneous mixing. The chamber rotation speed is adjustable - this permits to treat even products with weak bonds, without modifying their molecular structure.

- All possible blocks inside the mass are crushed, and the lumps are broken by CRIOX System, permitting to obtain at the end of the process dry powders, with a controlled final particle size distribution, ready to be riddled and packed.

- Application of CRIOX System minimizes times required to re-establish the line, wash, clean and inspect the plant and it permits to shift rapidly from a product campaign to another.

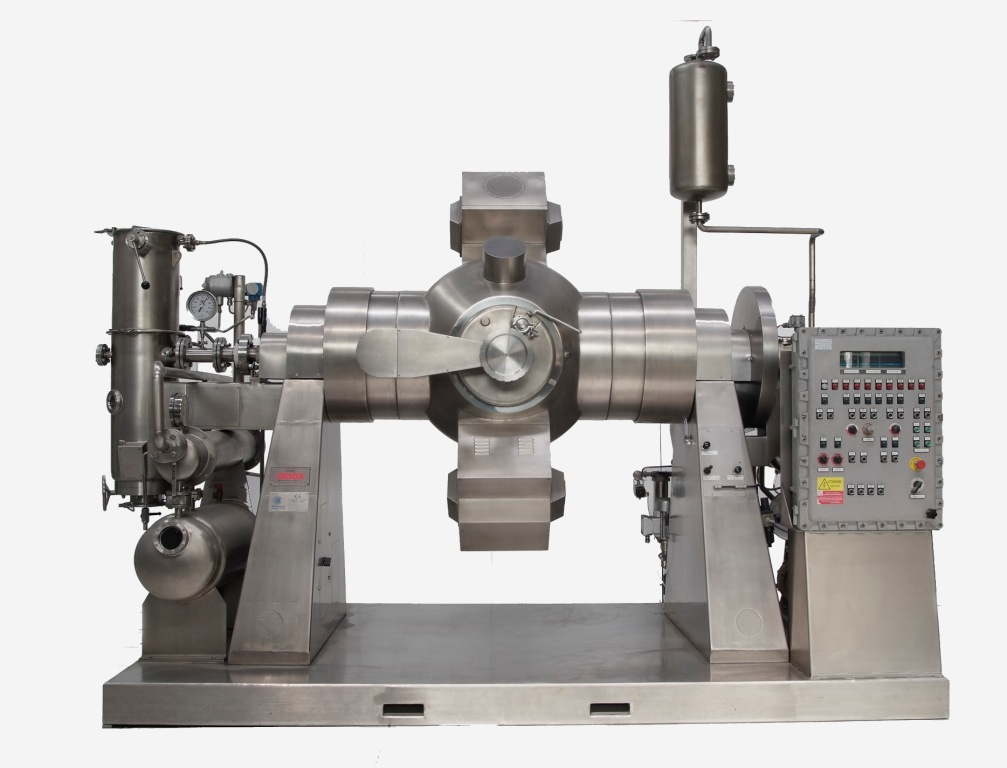

- CRIOX® System is the only rotary double cone dryer currently on the market, equipped with electrically operated lump breakers. This is a crucial feature, as electric motor-driven lump breakers offer exclusive performance and benefits, including:

o Rotating speed control

o Scheduling of operating cycles

o Constant torque with changing speed

o Absorption control

o Ventilated cooling

o Moreover, electric lump breakers ensure:

o Reliability and durability, also in heavy-duty

o Low maintenance

- Two sets of electric lump breaker blades inside the rotary chamber guarantee the best possible result, as it is an exclusive feature that drastically increases product surface exposed to evaporation and enhances system mixing effectiveness. Thanks to the chamber rotation, each lump-breaker set alternatively goes in and out the product, promoting self-cleaning when emerging.

- Lump breakers significantly reduce drying time, assuring the lowest possible residual humidity. They also allow operation at lower processing temperatures, preventing downgrading of the most delicate thermo sensitive products.

- The system can be used as an effective fast blender or homogenizer, as well as a granulator, limiting the subsequent use of the mill as much as possible.