Model description

-

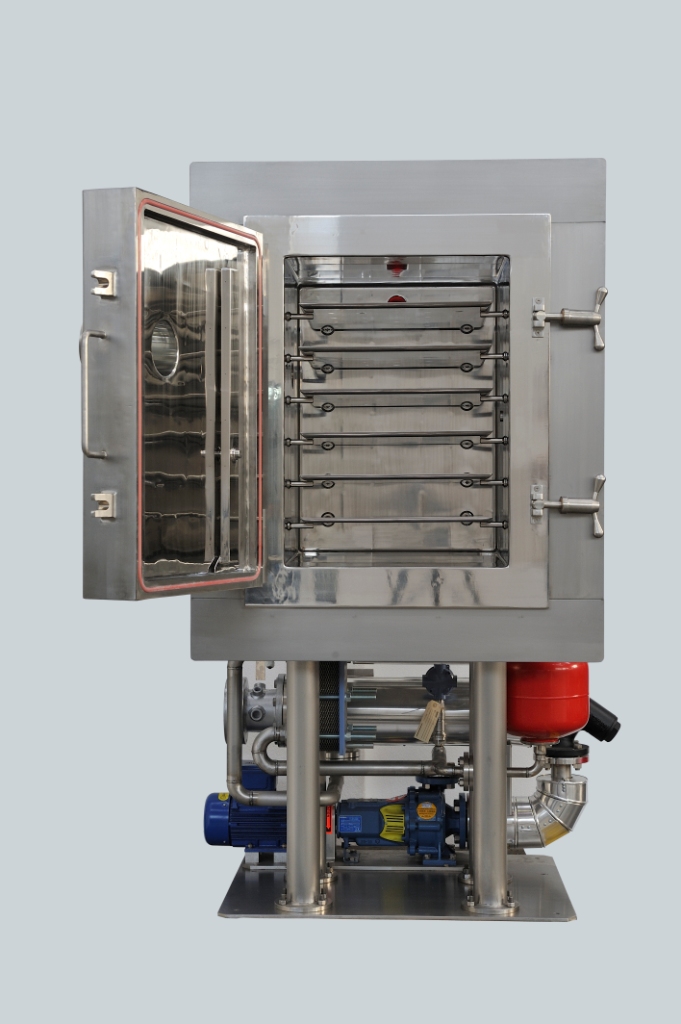

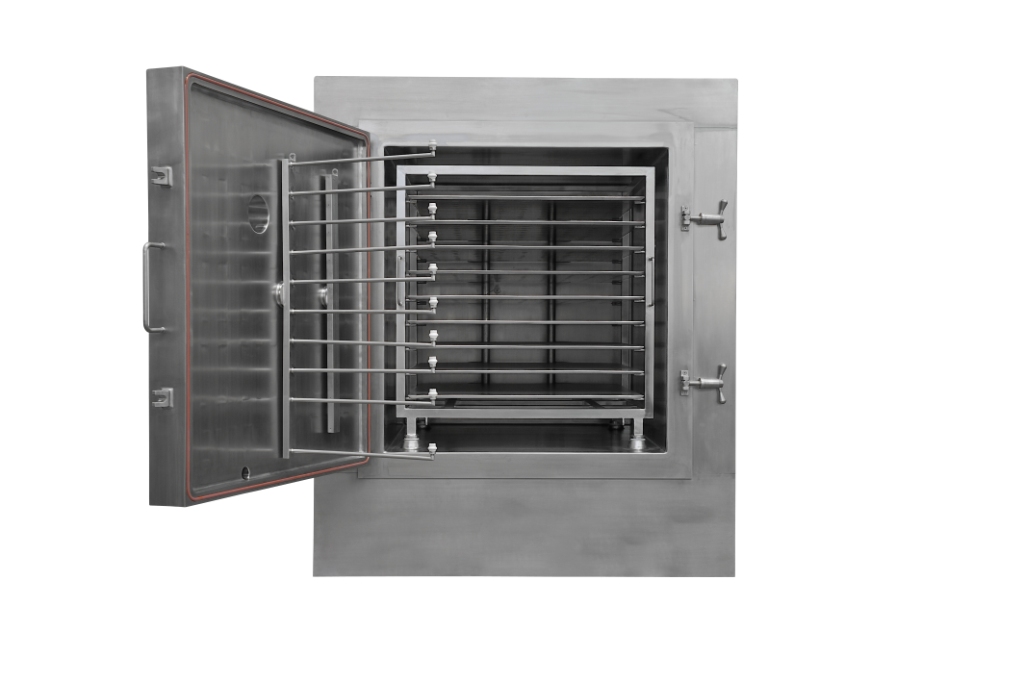

- The "particle-free" tray system allows to completely extract dried product without leaving any residues on the surfaces of the dryer. This is especially important in case of expensive substances.

- Precise machining of all parts and surfaces of the cabinet allows reaching a deep vacuum level in the cabinet and guarantees thorough and easy cleaning.

- To ensure the safety of drying process in case of using explosive solvents, the cabinet can be equipped with an automatic nitrogen purging system.

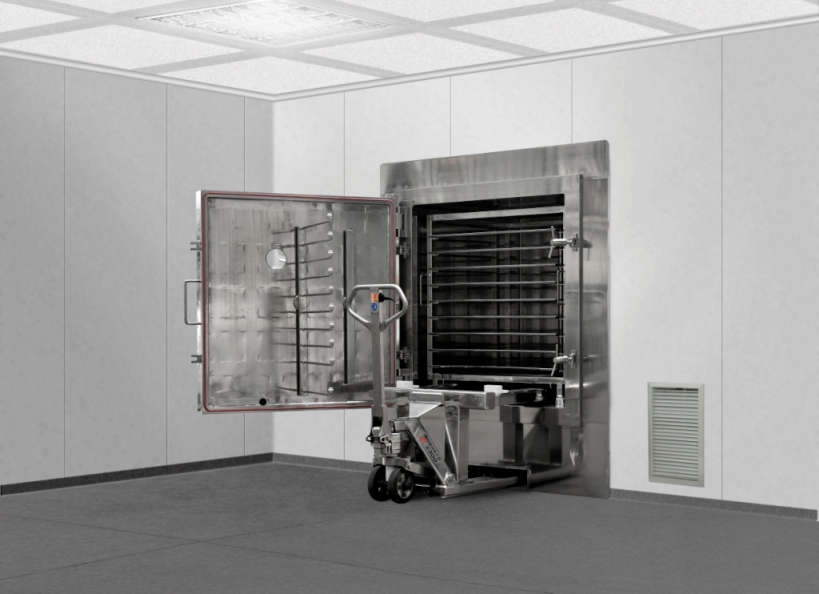

- For GMP application the cabinet can be installed "through the wall", when only the front panel and the door are located in a clean room, the rest of the structure is installed behind the wall in the technical room.

- Special design makes the doors completely gas-tight and resistant to deep vacuum.

- Recently Italvacuum introduced new automatic door opening / closing system. The door is operated by a ATEX compliant hydraulic system with vertical movement. This innovation, coupled with an automatic dryer loading and unloading system, provides the ideal solution for high toxic risk productions, preventing the personnel from having any contact with the product.

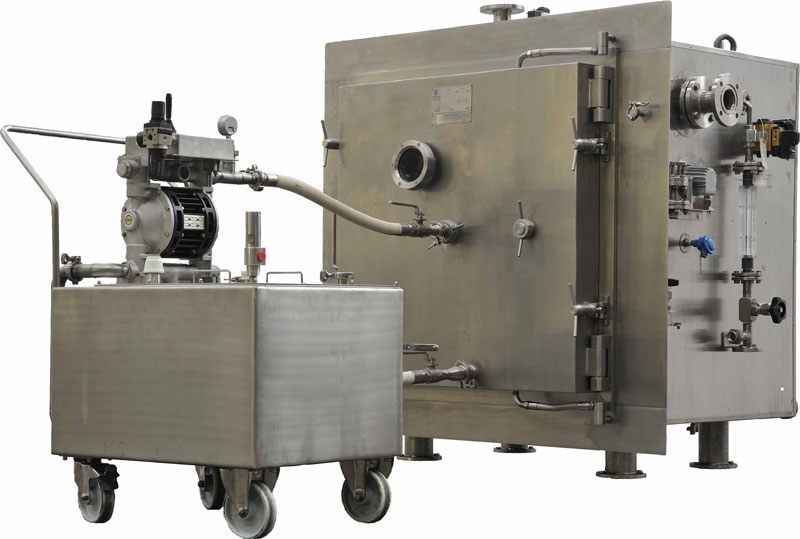

- C.I.P. MULTISPRAY® patented fast washing system guarantees perfect cleanliness of inner parts, using only a minimum amount of washing liquid and preventing the operator from coming into prolonged contact with possible product residues and solvents present inside the dryer. Drying chamber and inner plates can be washed and cleaned in just a few minutes, in a repeatable and certifiable way.