Model description

-

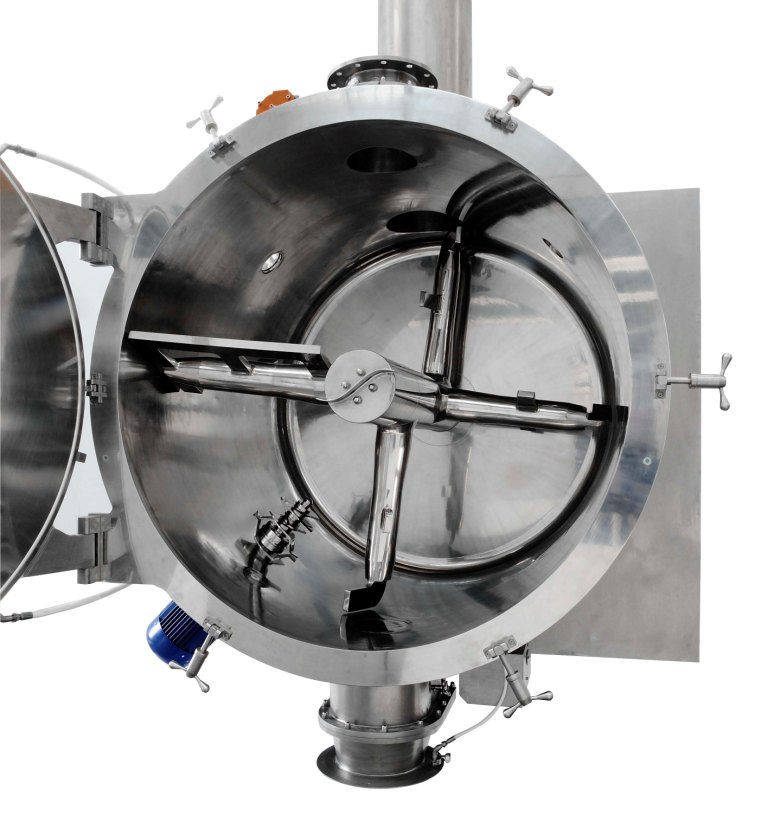

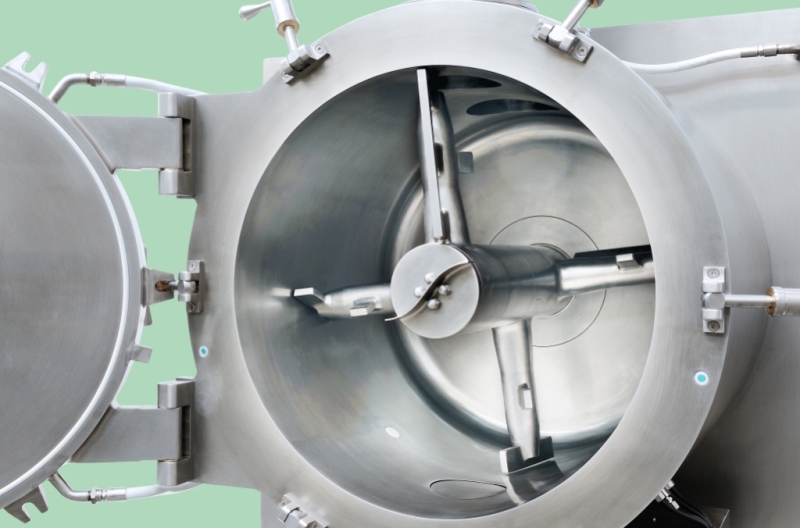

- Agitator profile designed to limit mechanical and thermal stress, making CosmoDry® System also the ideal solution for treating thermo-sensitive products;

- Gradual powdering of the product Homogeneity and uniformity of dried batch thanks to peculiar configuration of the agitator, which enables continuous stirring of the product and facilitates its thermal exchange;

- Agitator’s special features permit a reduction of product deposition to a minimum, making easy and efficient the unloading operation, for which a dedicated operation cycle has been introduced;

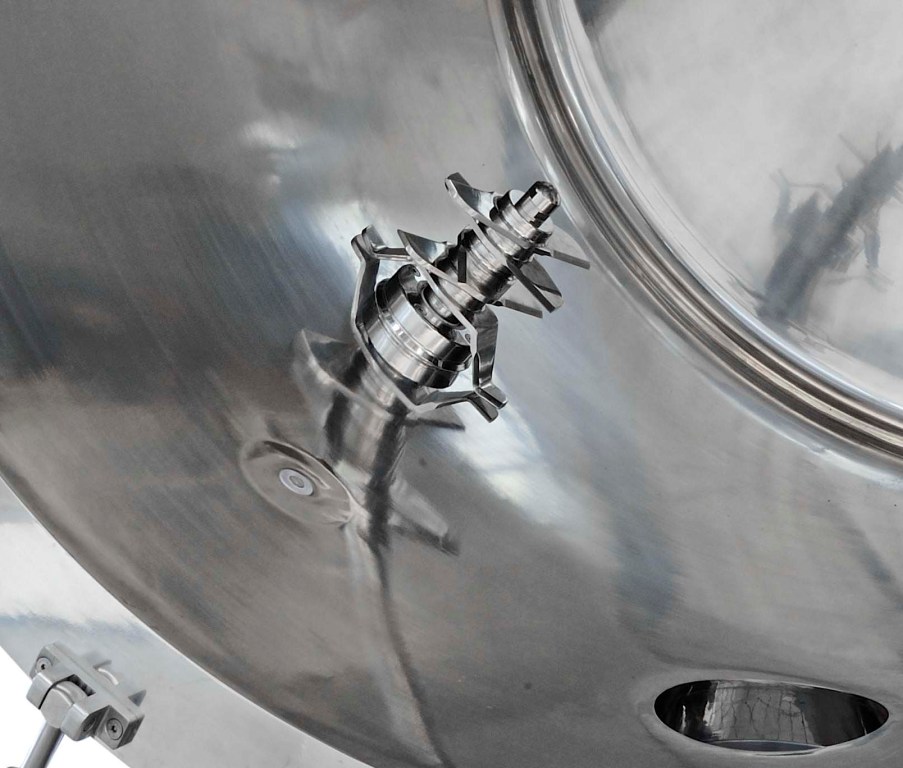

- Electrically operated lump breakers allow to powder and eliminate any possible agglomerates;

- One or two lump breaking groups can be installed inside the vacuum chamber as an option;

- The position of the lump breakers and the agitator profile are optimized in order to obtain the maximum mixing and powdering efficiency;

- The sealing systems guarantee absolute purity of the dried batch and perfect vacuum tightness;

- Very high final vacuum values can be reached during product processing;

- Further reduced drying times;

- The ease of dismantling the agitator leads to easier access for internal cleaning and inspection, which permits a vast reduction in machine stops during the changeover from one product batch to another;

- Very easy product unloading thanks to:

o total absence of friction points on the product;

o reduced gap between the agitator paddles and the wall of the drying chamber;

o specific unloading program;

- Total system automation capable of guaranteeing process reproducibility for all batches.