Language: english

- Industry 4.0

-

API Manufacturing

-

Herbal API Manufacturing

- Crushing of Herbal Raw Materials

- Liquid Extracts Preparation

-

Dense Extracts Preparation

-

Vacuum Evaporators

- Brands

- Kavalieriglass

- Promvit

- Rotary Evaporators

-

Paddle Dryers

- Brands

- Olsa

-

Vacuum Evaporators

-

Dry Extracts Preparation

- Tray Driers

-

Belt Driers

- Brands

- GIG Karasek GmbH

-

Spray Driers

- Brands

- BUCHI

-

Vacuum Driers

- Brands

- Italvacuum

- Olsa

-

Vacuum Pumps

- Brands

- Italvacuum

- Subcritical CO2 Extracts Preparation

- Supercritical СО2 Extracts Preparation

- Synthetic API Manufacturing

-

Herbal API Manufacturing

-

Raw materials & Materials preparation

- Storage and Transportation of Raw Materials and Semifinished Products

- Raw Materials and Materials Handling

-

Solid Dosage Forms

- Blending / Mixing

- Dry Granulation

-

Quality Testing for solid dosage forms

- Brands

- Bohle

- Charles Ischi AG

- RETSCH

- Wet Granulation

- Coating

- Tableting

- Encapsulation (Hard Capsules)

- Barrier technology

- Encapsulation (Soft Capsules)

- Tablet / Capsule Coating

- Printing on Tablets and Capsules

- Primary Packaging

-

Liquid Dosage Forms

- Preparation of intermediate product

-

Filling

- Washing of vials and ampoules

- Sterilization

-

Filling/ capping (pre-closing) of vials and ampoules

-

Filling and capping (pre-closing) machines for vials

- Brands

- Aseptic Technologies

- Bausch+Strobel

- CAM

- Comas S.r.l.

- Countec

- Dara Pharmaceutical Packaging

- FARMPROM

- GF S.p.A

- groninger

- Gustav Obermeyer

- I Holland

- I-Dositechno

- IMA

- JIH CHENG

- M.A.R. S.p.A.

- Marchesini Group

- OMAS TECNOSISTEMI

- Optima

- Pall

- Promvit

- ROTA

- SYNOPAC AG

- Syntegon - Bosch Packaging Technology

- Tofflon

- TRUKING TECHNOLOGY

- WATSON-MARLOW FLEXICON

- Zellwag Pharmtech AG

- ZIGLER

- Filling and sealing machines for ampoules

-

Filling and capping (pre-closing) machines for vials

- Lyophilization

- Vial capping

- External vial washing

- Sterilization of finished product and leak testing

- Foreign particle detection

- Bags filling

- Filling of polymer containers

- Syringes filling

- Barrier technology

- Packaging

- Primary packaging

- Secondary packaging

-

Semisolid Dosage Forms

- Base preparation, mixing, homogenizing

- Preparation of intermediate product

- Secondary packaging

-

Gaseous Dosage Forms

- Preparation of intermediate product

- Preparation of primary packaging materials and accessories

- Filling

- Labeling

- Secondary packaging

- Group packaging

- Secondary and Transport Packaging

- Cleaning of Equipment and Premises

- Cleanroom Technology

- Quality control

- Services

Brands

- Bohle

- Comi Condor

- Dividella

- ECI Packaging Limited

- Glatt

- HOSOKAWA MICRON Group

- IMA

- InterPharmTechnology®

- Italvacuum

- Marchesini Group

- Michael Kurako

- rommelag AG

- Sartorius

- SCHOTT

- SYNTEGON

- Urlinski

- МАКРОЛАБ ЛТД

a

b

c

d

e

f

g

h

i

j

k

l

m

n

o

p

q

r

s

t

u

v

w

x

y

z

а

б

в

г

д

е

ё

ж

з

и

й

к

л

м

н

о

п

р

с

т

у

ф

х

ц

ч

ш

щ

ъ

ы

ь

э

ю

я

Home

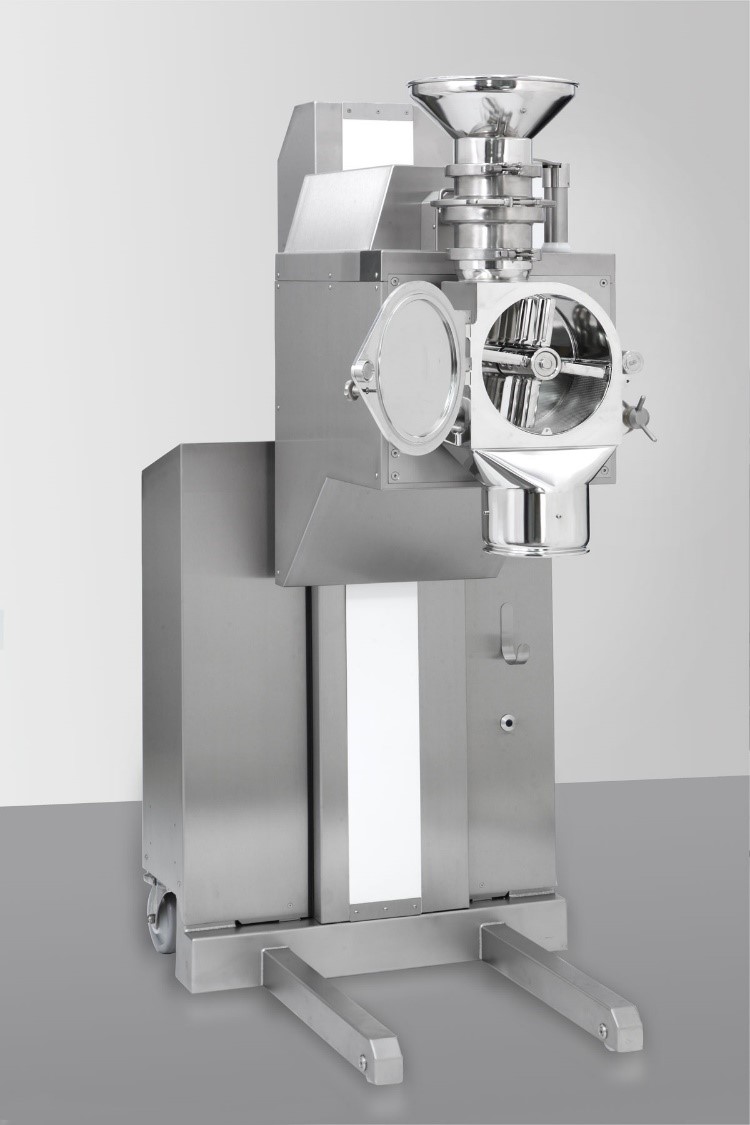

- Raw materials & Materials preparation - Raw Materials and Materials Handling - Grinding - Hammer Mills - Bohle - Hammer Mill – BTM